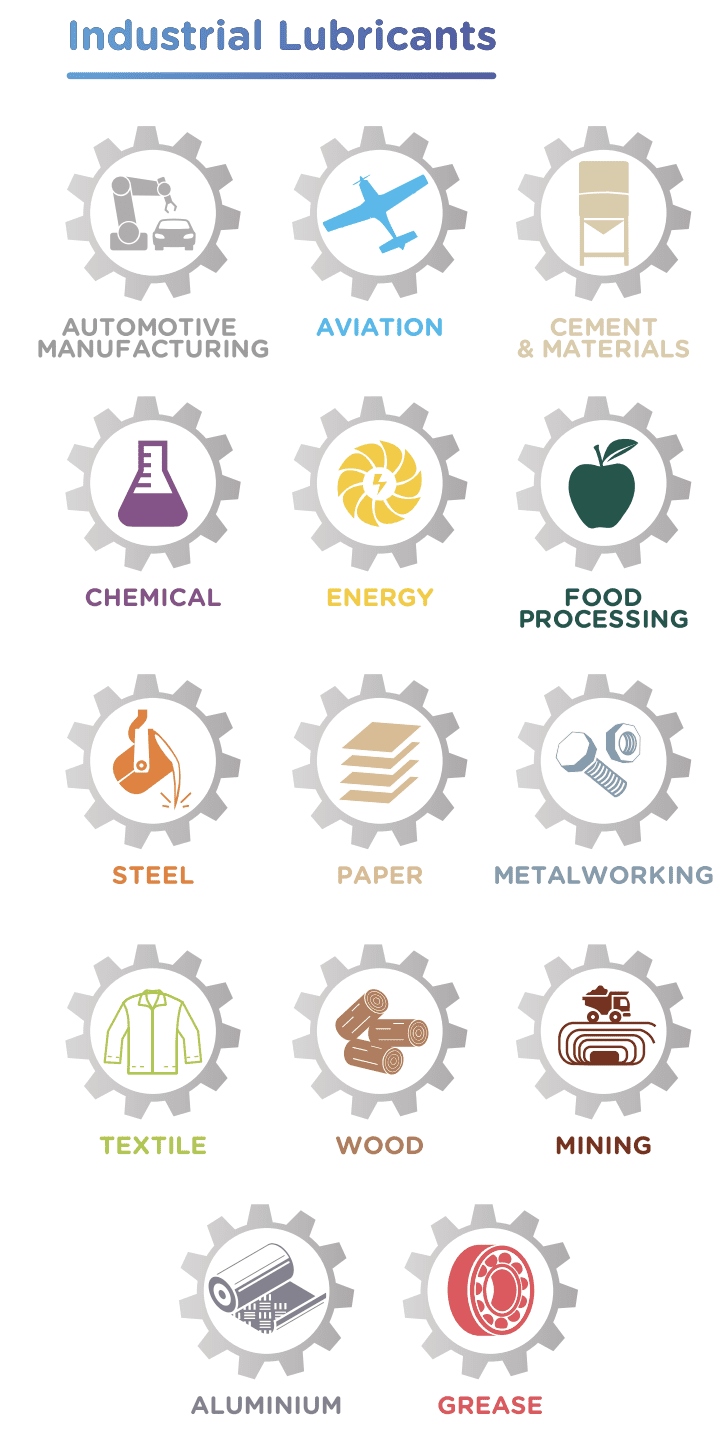

Industrial Lubricants

Addressing Diverse Industrial Applications

TotalEnergies provides a comprehensive array of industrial lubrication solutions tailored to the diverse needs of sectors such as power generation, manufacturing, metalworking, and mining. The product range is designed to ensure operational continuity and protect high-value machinery. This includes sophisticated offerings like high-performance hydraulic oils, circulating oils, compressor oils, and the specialized NEVASTANE line of NSF H1-registered Food Grade lubricants, which eliminates contamination risk in the food and beverage industry. By offering tailored solutions across all equipment types, TotalEnergies helps businesses enhance reliability and adhere to strict industry-specific standards.

High-Performance Fluids and Gas Engine Technology

A cornerstone of the industrial portfolio is the suite of high-performance fluids engineered for demanding conditions. For power generation, the NATERIA series of gas engine oils, such as NATERIA MX 40 and NATERIA MWX 40, stand out. These semi-synthetic and premium hydrocracked mineral oils feature low-ash formulations and high TBN (Total Base Number) values, specifically designed to meet the demands of the latest generation of steel piston engines operating at higher temperatures. Their exceptional thermal stability and detergent properties translate directly into extended drain intervals (up to 50% longer in some cases) and reduced specific lubrication oil consumption, significantly boosting a plant’s operational efficiency.

Beyond the Product: Services for Operational Excellence

TotalEnergies’ industrial commitment extends beyond the physical product to encompass value-added services aimed at predictive maintenance. These solutions include lubrication surveys to optimize product selection and usage, and the industry-renowned LubAnac oil analysis program. By performing detailed laboratory analysis of in-service lubricants, this service detects equipment wear and fluid degradation early, allowing for proactive maintenance planning. This shift from reactive to predictive maintenance minimizes unscheduled downtime, cuts operational costs, and ensures maximum machine lifespan, making TotalEnergies a critical partner in managing a facility’s total cost of ownership.